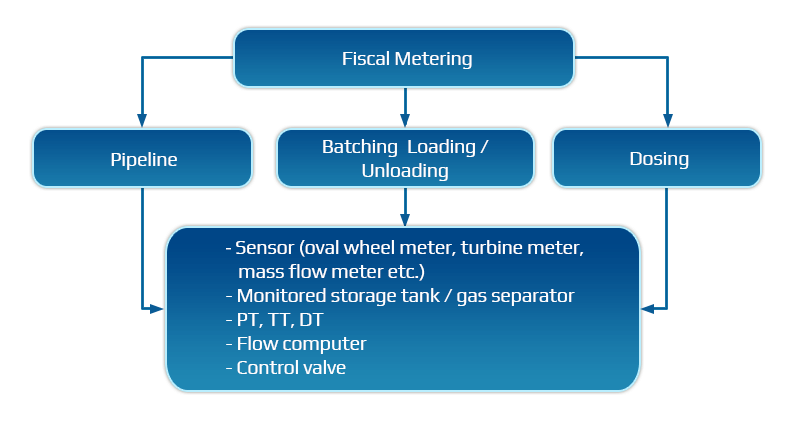

As a complete solution provider, we cover all needs, from consulting, engineering, manufacturing, testing, at Site installation and implementation of Compact Metering /Proving Systems based on our own components and technologies for:

- Batch Measurement: Loading / Unloading

- Continuous Measurement: Pipeline

- Blending and Additive Injection Units

- Dosing

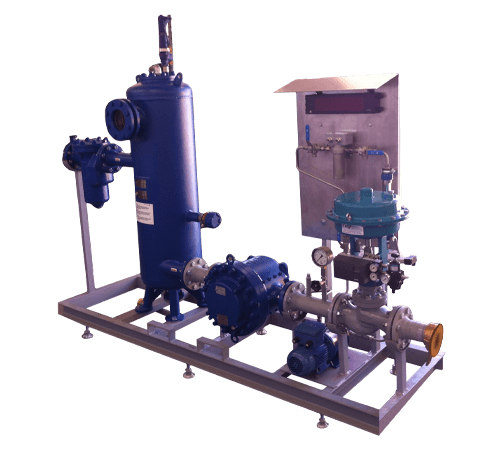

CUSTODY METERING PACKAGE

The Compact Metering System designed by BOPP & REUTHER MESSTECHNIK GMBH is a fully assembled automated Metering solution built upon a framed base that can be installed permanently or be portable to move and measure the amount of product being transferred

Our Metering/Proving Package a tailored solution reflecting the comprehensive understanding of International Measuring Directives and newest Metrological Regulations (MID, OIML, etc..).

Local normative or customer-specific requirements available could be evaluated and integrated into the design.

Internal Tests

Thorough tests are performed on each CMS before leaving our premises:

- Leakage test

- Calibration test of the Complete Measuring/Proving System

SIZING AND SELECTION

Properly sizing of the Metering SKID consists of choosing a Line-size that optimizes the trade-off between measurement error at minimum Flow rate and pressure loss and/or liquid velocity at maximum flow rate.

Metering SKID should be sized for the current average continuous production-flow rate.

DESIGN PARAMETER

The following Parameters are needed to design a suitable SKID-Solution:

- Application: Batch (Loading – Unloading) or Continuous Measurement

- Fluid being metered

- System Operating Flow Min-Norm-Max (m3/h)

- Operating Temperature (°C)

- Operating Pressure (bars)

- Operating Density (kg/m3)

- Operating Viscosity (mPa.s)

- Power Supplies Available

- Explosion proof Design

- Line Size / Piping – ANSI Class

MODULAR SOLUTION

We provide modular complete solution using our own products and those from other leading manufacturers in detail consisting of:

- Shut-Off Valves

- Filter and Air Release Element

- Process Instrumentations (Temperature – Pressure – Density)

- Sensing (Metering) Element (Mass or a Volumetric flowrate)

- Proving Connection

- Control Valve

- Flow Computer

Please Note:

- For LPG (Liquefied Gas), a Dynamic fluid pressure control must be included in the Metering Line in order to prevent vaporization.

- The pressure control loop is implemented in the batching flow computer, using continuous signal interchange with Pressure transmitter installed in the metering Line.

- It triggers the set-stop valve to increase back pressure in order to maintain the fluid by constantly monitoring its vapor pressure.

- Oil and Gas

- Chemistry

- Mechanical and plant engineering