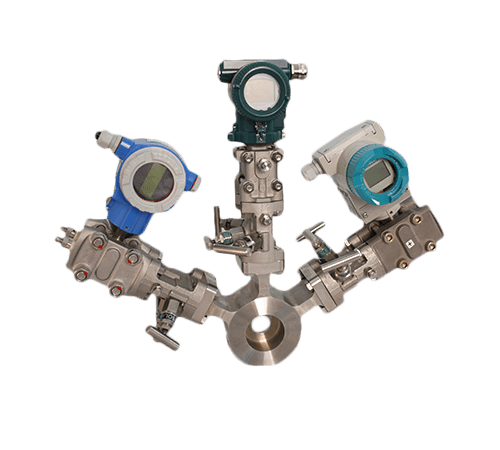

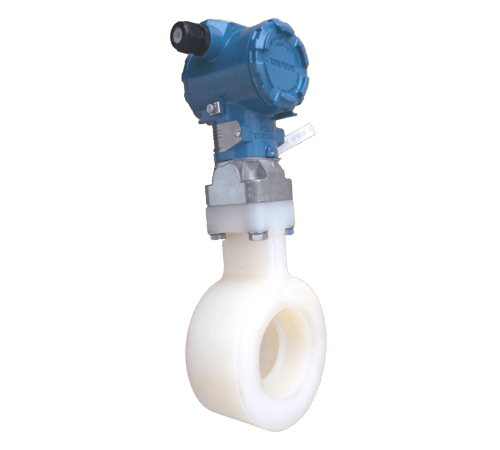

The compact orifice Oriflow is used for flow measurements of conductive and non-conductive fluids, gases and vapours in all industrial branches.

Our strategic business unit (SBU) METRA Energie-Messtechnik has taken over this area. Our team will be happy to answer any questions you may have.

Application:

Applications include flow measurements (volume / Mass) for balancing (compressed air systems, heat carries, vapours, chemical products, for examples), process control and high throughput applications, redundant solutions for safety applications

Technical data

| Nominal size | DN15 to DN300 (1/2“ to 12“), bigger sizes on request |

| Process connection | Sandwich, Flanges according to DIN or ANSI |

| Material | Stainless steel, Hastelloy, Tantalum, Titan, PVDF, Monel |

| Flow Range | 0.2 to 150,000 m³/h (52.83 to 39,625808 gal/h) |

| Accuracy | up to ±0,6% |

| Viscosity |

-40°C up to +400°C |

| Process temperature | up to PN100 (up to 320 bar / 4,641 psi on request) |

| Process pressure | current output / Foundation Fieldbus / Profibus A |

| Ex-protection | Flame proof or intrinsically safe |

Special features

- dry calibration

- high repeatability

- easy installation without pressure lines

Characteristics

- highest market acceptance already over 10,000 units in operation worldwide

- extremely rugged and stable measuring instrument

- suitable for extreme applications

Product Variants Oriflow

| Main Features | Options | |||||||||||

| Nominal Size available (in DIN or ANSI) |

Dimension / Standard |

Nominal Pressure available |

Temperature Range | Material available | Valve Block | Valve Block new |

Steam Angle horizontal |

Steam Angle vertical |

Pressure seals | others | Special Features | |

| Model D | DN15 – 150 1/2″ – 4″ |

70 mm | max. PN63 Class 600 |

-20° – 170°C (-4° – 338°F) |

1.4408, 1.4409 | X | X | X | only as cast version / with steam angle up to 280°C (536°F) | |||

| Model D | DN200 – 1000 5″ – 40″ |

40 – 60 mm | max. PN63 Class 600 |

-20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 or special |

X | X | X | X | with steam angle up to 280°C (536°F) | ||

| Model G | DN4 – 15 | 150 mm | max. PN40 | -20° – 170°C (-4° – 338°F) |

1.4571 | X | X | X | ||||

| Model I | DN15 – 150 1/2″ – 4″ |

25 mm | PN40 Class 600 |

-20° – 170°C (-4° – 338°F) |

1.4571 | X | X | X | ||||

| Model L | DN6 – 150 1/2″ – 6″ |

max. PN325 Class 2500 |

-20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 or special |

X | X | X | with steam angle up to 280°C (536°F) / lens seal or ring joint | ||||

| Model M | DN6 – 125 | max. PN325 | -20° – 400°C (-4° – 752°F) |

1.4571 | X | |||||||

| Model N | DN15 – 150 1/2″ – 4″ |

40 – 60 mm | max. PN63 Class 600 |

-20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 | X | X | X | X | |||

| Model O | DN15 – 200 1/2″ – 6″ |

60 mm | max. PN160 Class1500 |

-20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 or special |

X | X | X | with steam angle up to 280°C (536°F) | |||

| Model S | DN150 – 1000 2″ – 20″ |

max. PN100 Class 900 |

20° – 400°C (-4° – 752°F) |

1.4571, 1.4404 or special |

X | X | first shut-off as single or double welded version | |||||

| Model T | DN15 – 500 | 60 mm | max. PN40 | -20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 or special |

X | temperature extension | |||||

| Model U | DN15 – 500 1″ – 20″ |

max. PN100 Class 900 |

20° – 400°C (-4° – 752°F) |

1.4571, 1.4404 or special |

X | |||||||

| Model Z | DN15 – 150 1/2″ – 4″ |

25 mm | PN40 Class 600 |

-20° – 170°C (-4° – 338°F) |

1.4571, 1.4404 or special |

X | X | X | ||||

| ORIKON | DN15 – 250 | 65 mm | PN40 | -20° – 350°C (-4° – 662°F) |

1.4571, 1.4404 | |||||||

- Oil and Gas

- Chemistry and pharmaceutical

- Mechanical and plant engineering

- Energy and power plants