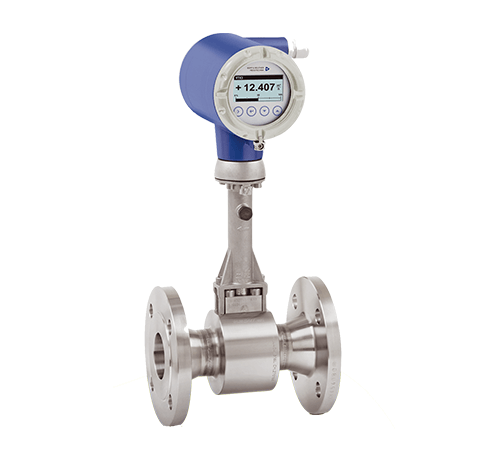

Vortex meter VTX 3

Application:

- measurement of saturated steam and superheated steam

- heat quantity measurement of steam and hot water

- consumption measurement of industrial gases

- safety-relevant measurements in SIL applications

- consumption measurement in compressed air networks

Technical Data

| Nominal size | DN15 to DN300 (1/2“ bis 12“) |

| Process connection | Sandwich, Flanges according DIN or ANSI |

| Material | Standard:1.4404/316L / Option: Hastelloy C-22 |

| Flow Range | 0.36 to 1,840m³/h (0.095 to 486.08 gal/h) |

| Accuracy | ±0.75% of measured value |

| Repeatability | -40°C to +240°C (-40°F to +464°C) |

| Viscosity | max. 100 bar |

| Process temperature |

4-20mA current output HART® (passive), pulse, Status, frequency, limit switch |

| Process pressure | Graphic display |

| Ex-protection | ATEX II2G- Ex ia IIC T6…T2Gb |

Special features

- latest modern technology for signal filtering -AVFD (Advanced Vortex Frequency Detection)

- integrated pressure and temperature compensation

- temperature compensation for saturated steam included as standard

- integrated nominal width reduction

- integrated gross and net heat quantity calculation for steam and hot water

- comprehensive communication options

Industries

- chemistry

- oil & gas

- power plants

- food & beverages

- pharmaceutical

- paper & pulp

- automobile industry

- iron, steel and metal

- Oil and Gas

- Chemistry and pharmaceutical

- Mechanical and plant engineering

- Food and beverage

- Energy and power plants

Vortex meter VTX 2

The VTX vortex meter is used for flow and volumetric measurements of conductive and non-conductive fluids, gases and vapours in all industrial branches.

Application:

Applications include volumetric measurements for balancing (compressed air systems, heat carriers, vapours, chemical products, for example), process control and high throughput applications, thermal oil.

Technical data

| Nominal size |

DN15 to DN300 (1/2“ to 12“) (larger connections on request) |

| Process connection | Sandwich, Flanges according to DIN or ANSI |

| Material | Stainless steel |

| Flow Range |

0.4 to 20,000 m³/h |

| Accuracy | up to ±0,6% |

| Repeatability | -40°C up to +260°C / 450°C (-40°F up to +500°F / 842°F) |

| Viscosity | up to PN100 |

| Process temperature | current output with HART® or current pulses and scalable pulse output according to NAMUR |

| Process pressure | eight digit display up front with operating keys, DTM and AMS drivers are available |

| Ex-protection | Flame proof or intrinsically safe |

Characteristics

- Extremely rugged and stable measuring instrument

- maintenance-free

Special features

- insensitive to pulsations, pressure bursts and temperature shocks

- with auto-adaptive digital signal processing

- with P- and T-correction

- 3 simultaneously and independently usable signals (current output HART®,pulses)

- with an optional shut-off valve, the sensor and the electronics can be replaced under process conditions

- optional with complete measuring section and universal flow computer for pressure and temperature compensation

- Oil and Gas

- Chemistry and pharmaceutical

- Mechanical and plant engineering

- Food and beverage

- Energy and power plants